|

Language : 日本語 | English | 简体中文 |

This page is excluded from search for reasons such as discontinued.

Products GuideDIMAC provides 18 feeders in 5 categories. This page introduces them by functions. We hope you can take best product for your use.

Please see here about option products. And about the price, please see here. About obsolete products, please see another page. Please see here about the product warranty. NC Roll Feeder : RF-A SeriesThe standard model whose release mechanism is based on compressed air.Maximum stamp speed is up to 300spm and maxixmum material thickness is up to 3.2mm. For more details about RF-A series, please see another page. More information also is shown with click model name in the table below.

NC Twin Roll Feeder : TRF SeriesThis product is equipped with C-type frame. A work can be supplied from the front. This is designed and best choice to deal with short plates. For more details about TRF series, please see another page.

High-Speed NC Roll Feeder : MS-C SeriesThis product can follow fast stamp speed. The release mechanism driven by the stamp motion of press machine. Maximum stamp speed is up to 700spm. For more details about MS-C series, please see another page.

Airless High-Speed NC Roll Feeder : HS-B SeriesThe high-end model which equips electromagnetic release mechanism. It follows 1000spm stamp speed with a private rotary encoder. Electromagnetic mechanism need no compressed air and realise numerical control for pressing force to material. For more details about HS-B series, please see another page. More information also is shown with click model name in the table below.

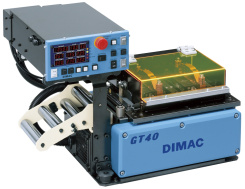

NC Grip Feeder : G SeriesThis product hold material by surface of grip (not by line of roller) and carry it. This method has advantage of avoiding damaging material compared with rollers. In the same way as HS-B series, G series equips electromagnetic release mechanism and it doesn't need compressed air. The GT40, feed length max 40mm, press speed will follow up max 1000spm. The GL110, feed length max 110mm, press speed will follow up max 600spm. For more details about G series, please see another page.

The Key to Select SeriesEach series of our feeder has various mechanism that below table shows.

As a result of above mechanism, each series have below characteristic.

All products of HS-B series and GT40 /GL60 synchronize operation with press machine by a private rotary encoder (rotation sensor). Other models do so by two synchronizing signal. The products which are syncronized by a rotary encoder cannot cope with servo press machine. About the use outside JapanOur NC feeders are manufactured on the basis of specifications for domestic (in japan) use. When the machine is exported, make sure that it is provided with safeauards required in the destination country before starting operation. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||