Standard NC Roll Feeding Machine : R Series

The standard model whose release mechanism is based on air cylinder.

The maximum stamp speed is 200 spm and the material width is 3.2 mm maximum. Four models according to material width are presented.

The controller 410C automatically adjusts the optimum acceleration from the specified feed length and press speed. A level meter that monitors the load of the feed motor is also installed as standard. In addition, the standard equipment is a 10x feed length specification, which was an option for the previous model RF-A series, and is equipped with the same performance as the high acceleration specification.

For installation, two signals for synchronization with stamping and air supply are required.

We have options available as needed, so please check.

About comparison to other series, please see products Guide.

For faster stamp speed, we suggest H Series. And to deal with short material, T series is also suggested.

Product Specifications

| R20 | R30 | R40 | R50 |

|---|

| Limit of Matrial | Max. Width | 200mm | 300mm | 400mm | 500mm |

|---|

| Max. Thickness | 3.2mm |

|---|

| Max. Stamp Speed | 200spm |

|---|

| Material Feeding | Method | Roller + Servomotor |

|---|

| Feed Length | 最大9999.99mm

Adjusted by 0.01mm unit. |

|---|

| Feed Speed | Automatic calculation * |

|---|

Standard Load

Width / Thickness | 80/3.2mm

200/2.0mm | 80/3.2mm

200/2.0mm

300/1.6mm | 80/3.2mm

200/2.0mm

400/1.6mm | 80/3.2mm

200/2.0mm

500/1.6mm |

|---|

| Material Pressing | Method | Spring |

|---|

| Pressing Capacity | MAX 1960N

Adjusted by screws. |

|---|

| Material Releasing Method | Air Cylinder |

|---|

| Required Power Supply | Three phase or single phase , 50/60Hz |

|---|

| Product Weight | 42kg | 49kg | 55kg | 61kg |

|---|

* Calculated by the press rotational speed settting and the feed angle setting.

Feed performance table of R series are shown in the table below.

Max.feed lengths(mm) under varied speed and feed angles.

Details can be confirmed on the feed performance computing form .

.

Stamp Speed

[spm] | Max. Feed Length [mm] |

|---|

| Normal Type |

|---|

Feed Angle

150° | Feed Angle

180° | Feed Angle

210° |

| 200 | 28 | 42 | 60 |

|---|

| 160 | 46 | 70 | 98 |

|---|

| 120 | 88 | 131 | 181 |

|---|

| 80 | 207 | 286 | 365 |

|---|

| 60 | 338 | 443 | 548 |

|---|

| 40 | 600 | 757 | 914 |

|---|

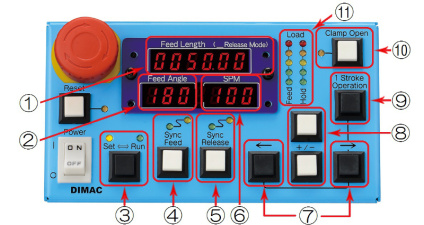

Controller 410C

Explanations in the panel are English only.

- Indication of Feed Length setting.

- Indication of Feed Angle setting.

- Continuous press operation display of the angle used for feeding during .

- Selector switch, setting mode or operation mode.

- Feed synchronous operation switch.

- Release synchronous operation switch.

- Indication of spm setting.

- Continuous press operation :Actual press spm display.

- ← / → switch.

- Run: Inching feed.

- Push the "→" switch while holding down the "1 stroke operation"switch, and 1 stroke feeds.

- Set: Move to the item to be set change.

- +/-switch.

- Run: Push the "+" switch while holding down the "1 stroke operation"switch. Feed speed of 1 stroke can be changed.

- Set: Change the value of the setting item.

- 1 Stroke Operation switch

- It can not be operated in this switch alone. Used in conjunction with the "→" switch.

- Roll open and close switch.

- Indication of servo motor load monitor .

- Patent application already.

Controllers of J Series have same appearance. But each controller is not unusable with the other machine because its own parameters are set. Moreover, it is not compatible with other models.

Information

2018/10/01

The setting method of the release mode of J series, R series, and T series will be changed.

another page

2017/2/23

Added single output mode of work shortage sensor signal.

Please check the contents from here.